CELL3DITOR: PRINT YOUR ENERGY

The Cell3Ditor project is designed to enable the quick deployment of 3D mass manufacturing technology of SOFC stacks.

CELL3DITOR Project ended in 2020. The technology developed thanks to CELL3DITOR led to a second project: HyP3D. To know more visit HyP3D website.

The main goal of the Cell3Ditor project is the development of a 3D printing technology for the industrial production of SOFC stacks by covering research and innovation in all the stages of the industrial value chain.

About Cell3ditor

The Cell3Ditor project is supported through the European Commission’s Fuel Cells Hydrogen Joint Undertaking (FCH 2 JU).

The Cell3Ditor project is designed to enable the quick deployment of 3D mass manufacturing technology of SOFC stacks.

OBJECTIVES

The main goal of the Cell3Ditor project is the development of a 3D printing technology for the industrial production of SOFC stacks by covering research and innovation in all the stages of the industrial value chain.

The main goal of the Cell3Ditor project is the development of a 3D printing technology for the industrial production of SOFC stacks by covering research and innovation in all the stages of the industrial value chain.

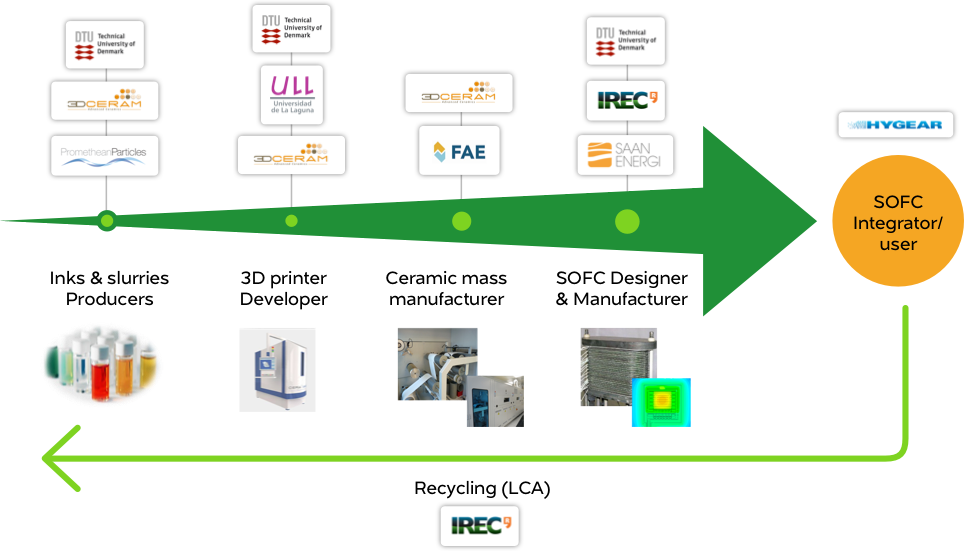

Scheme of the value chain of the Cell3Ditor

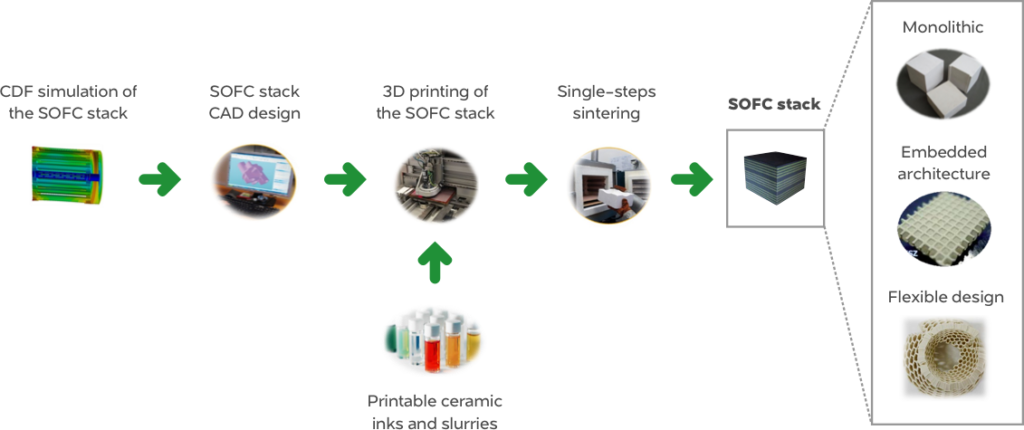

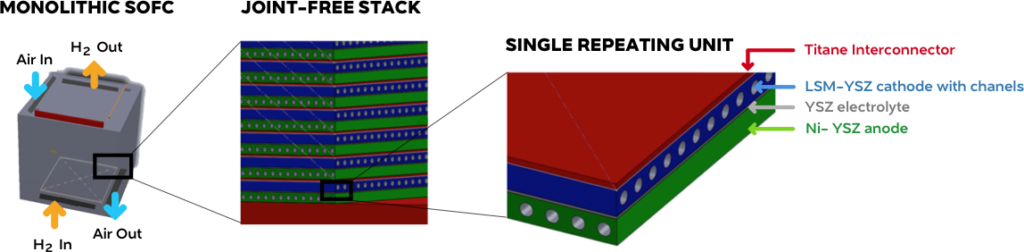

All-ceramic joint-free SOFC stacks with embedded functionality (fluidics and current collection) will be fabricated in a two-step process (single-step printing and single-step sintering) to reduce in energy, materials and assembly costs while simplifying the design for manufacturing and the time to market.

Scheme of the Cell3Ditor process

Structure of the Cell3Ditor product. A monolithic SOFC stack printed by a 3D multimaterial printer.

Activities

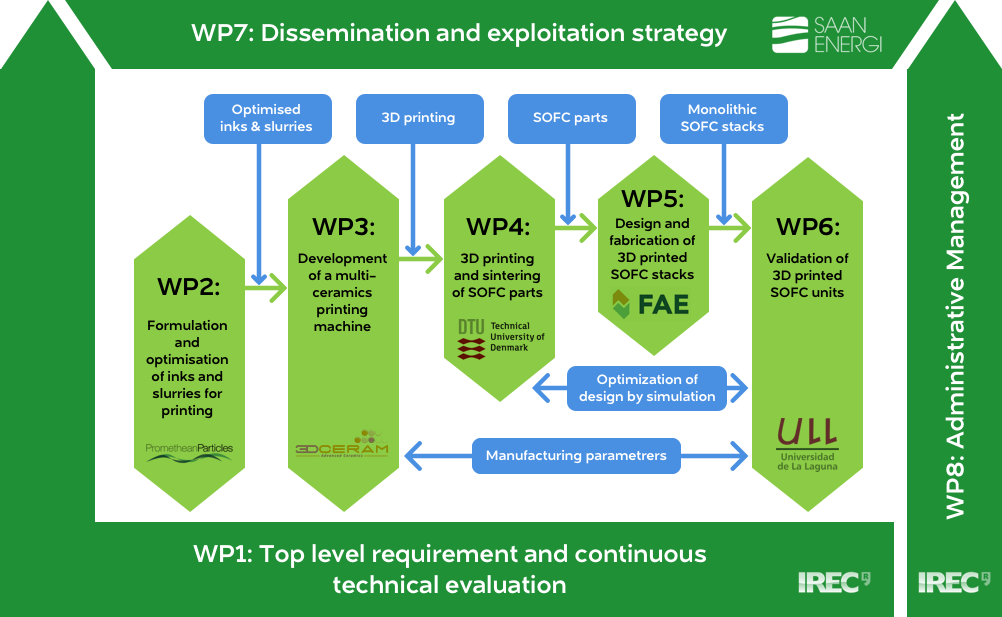

The Cell3Ditor project is being developed by a consortium of 8 partners that participate in different interrelated activities coordinated by IREC. The following figures show the responsible for each activity and the relation between all the tasks that form the project.

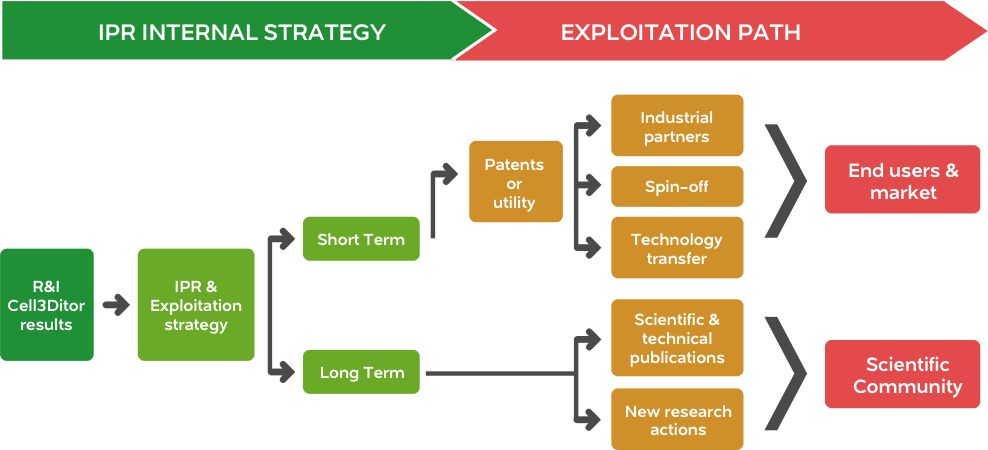

PROJECT STRATEGY

Funded by: